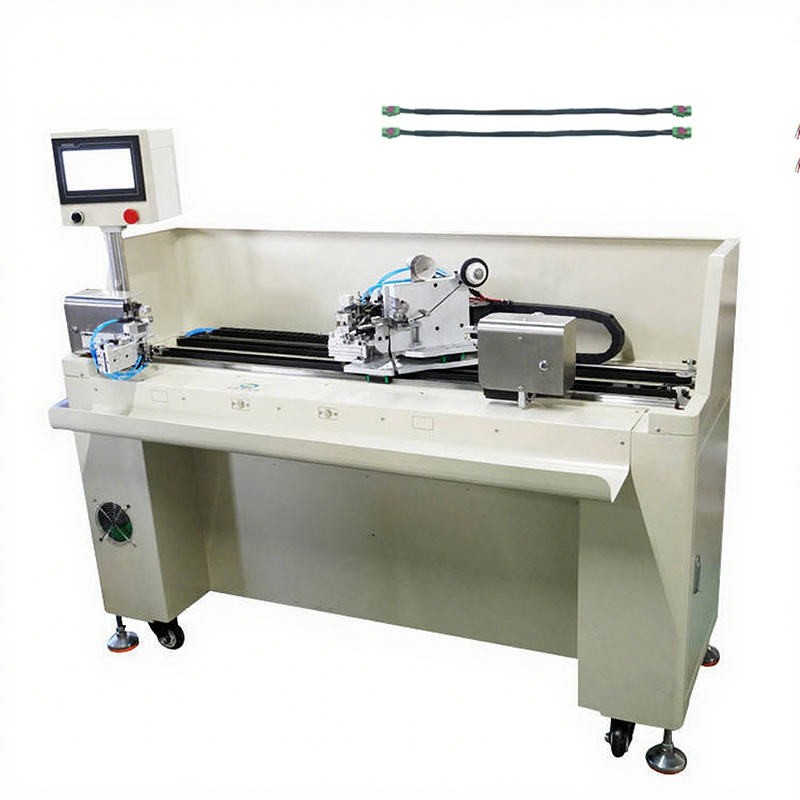

Automatic Tape Winding Machine High-Precision Automated Wire Wrapping Equipment

Automatic tape winding machine with a user-friendly human-machine interface and an intelligent design that spans the entire processing range. This equipment uses a closed-loop stepper drive, providing enhanced stability and precision , making it an ideal choice for high-precision tape winding processes.

Product Features

- Automated Functionality: Features automatic winding and cutting functions , with adjustable winding length and number of segments.

- Excellent Performance: Processing capacity is 8~30 seconds per piece, depending on the number of winding segments and length.

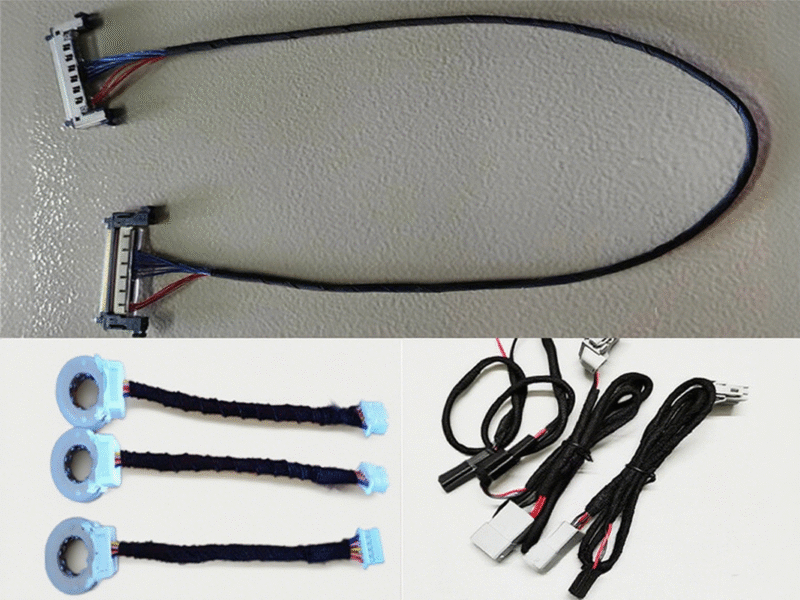

- Broad Applicability: Applicable to products with a diameter of 2-10mm , and supports various tape types such as PVC, fleece, and acetate.

- Precise Control: Adopts a full digital control method and uses a closed-loop stepper drive to ensure enhanced stability and precision.

- Reliability and Durability: The machine’s structure is reliable and rational , using mature technology for a low failure rate, high efficiency, and simple maintenance.

| Model | SR-CR10 |

| Function | 1.Automatic winding and cutting 2.Adjustable winding length and number of sections |

| Processing capacity | 8~30s/pcs (depending on the number and length of winding sections) |

| Processing specifications | Diameter 2-10mm |

| Tape type | PVC fleece, acetate… (requires additional installation for tape with release paper) |

| Tape width | 9~19mm |

| Winding length | Standard machine 900mm (customizable with an extended version) |

| Control method | Full digital control |

| Power supply | Single-phase/three-phase AC220V |

| Compressed air | 0.6MPa |

| Operating temperature range | 5℃~40℃ Ambient temperature |

| Operating humidity range | 30%~80%RH Non-condensing |

| Warranty period | 1 year (excluding consumables) |

| Dimensions | 1500mm*500mm*1250mm |

| Weight | 200kg |