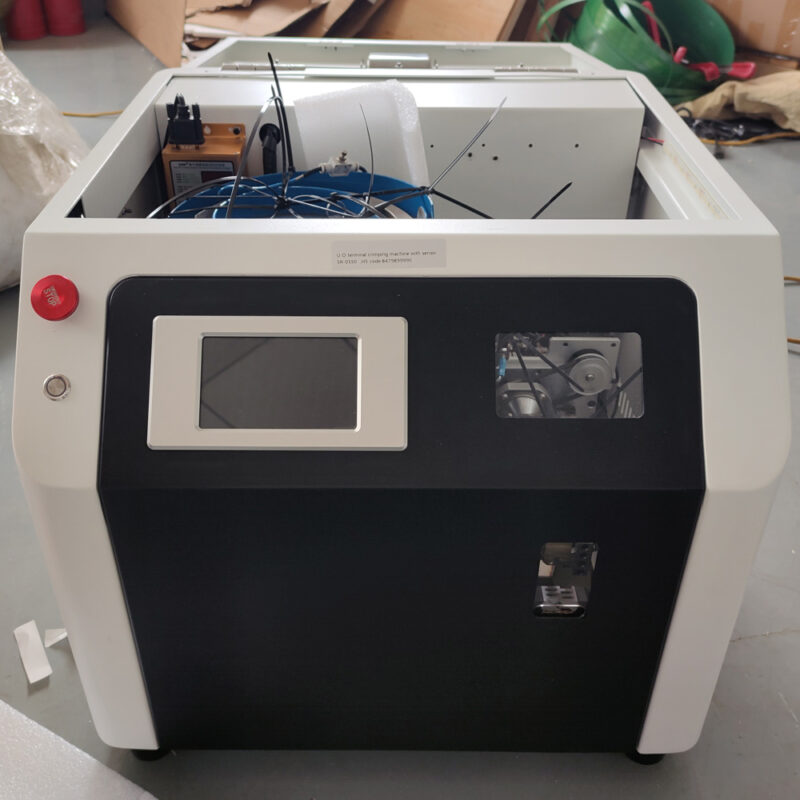

SR-510UO Ring & Fork Terminal Stripping Crimpping Machine

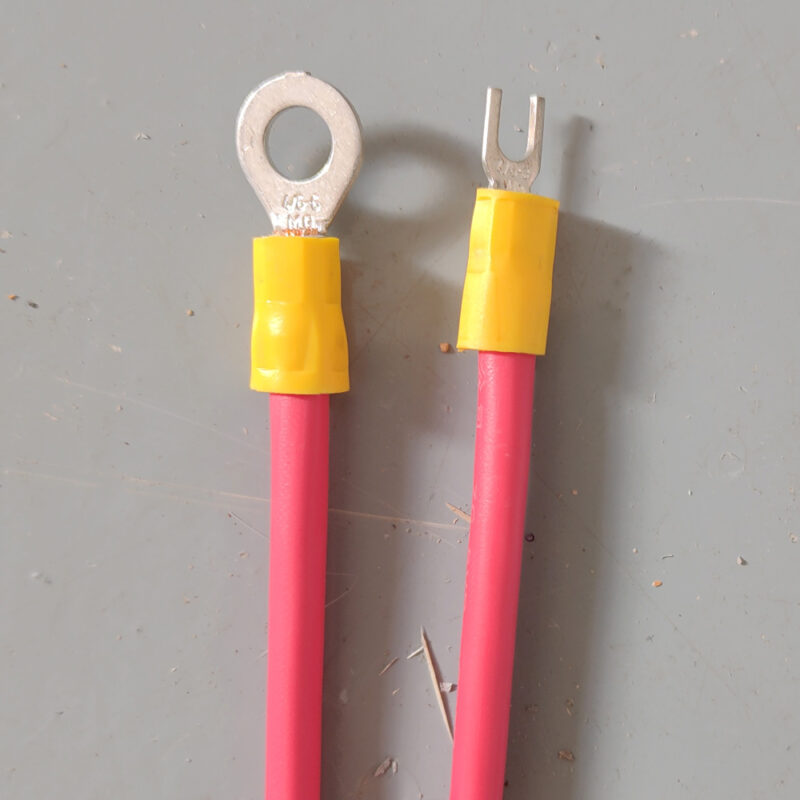

This advanced semi-automatic wire processing machine is specifically engineered for precise and efficient crimping of a wide range of common terminals, including fork terminals (also known as U-type or Y-type terminals) and ring terminals (also known as O-type terminals or ring lugs).

The machine seamlessly integrates the core functions of wire stripping, twisting, and terminal crimping, significantly boosting production efficiency and product quality for applications in automotive, electrical, and industrial fields.

⦁ Versatile Terminal Compatibility: The machine’s design for insulated ring terminals and fork terminals, providing broad application flexibility.

⦁ High Production Rate: Capable of achieving a high output of 1000 pieces per hour, a key advantage for large-scale manufacturing.

⦁ Efficient, Tool-Free Changeover: The system uses interchangeable hoppers for terminals, allowing for quick, tool-less replacement of terminal types, thus minimizing production downtime.

⦁ Precision Digital Control: Equipped with a motor-driven clamping mechanism, the machine provides digitally adjustable clamping force, ensuring high-quality, consistent crimps every time.

⦁ Smart Operation: With the capacity to store up to 100 processing programs, it enables quick recall for different jobs, ensuring consistent results and ease of operation.

| Name | Ring & Fork Terminal Stripping Crimpping Machine |

| Function | stripping twisting and crimping in one work step |

| Pressure of air source | 0.5-0.7mPa (clean air) |

| Motor power | 400w |

| Working Voltage | AC220V, 50HZ/60HZ |

| Stripping length | max 65mm |

| Applicable wire | 0.3-6mm², crimping length up to 12mm |

| Crimping Motor | Servo motor, Crimping force control program |

| Control way | touch screen+PLC+driver |

| Motor style | motor/Imported ball screw |

| Size and weight | 56*47*49cm, 80kg |