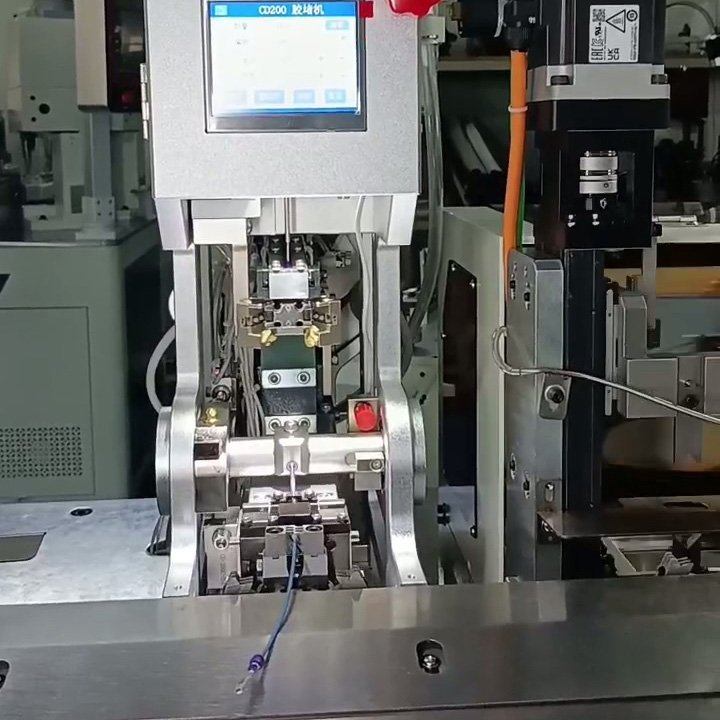

Dual End Wire Stripping & Crimping Machine with Waterproof Seal Insertion

This machine delivers unmatched efficiency and reliability for demanding waterproof wiring applications. By integrating automatic wire feeding, cutting, stripping (both ends), waterproof seal insertion (both ends), and terminal crimping (both ends) into one seamless process, it offers:

- Significant Cost Savings: Drastically reduces labor costs and material waste through precise, automated operation.

- Superior Product Quality: Ensures consistent, accurate processing of wires from AWG #22 to #14, guaranteeing secure, waterproof connections crucial for product longevity and safety.

- Boosted Productivity: Achieves high output rates (up to 950 pcs/hour), allowing customers to meet high production demands and tight deadlines.

- Reduced Rework & Defects: Advanced detection systems minimize errors, ensuring high yield and reliable finished products, ultimately enhancing customer satisfaction.

- Versatile Application: Ideal for industries like automotive, appliances, and electronics where precise, sealed wire harnesses are essential.

|

Power

|

2500W

|

|

Weight (KG)

|

700

|

|

usage

|

Cutting Stripping & Crimping and Waterproof Seal Insertion

|

|

place of origin

|

China

|

|

Guangdong

|

|

|

brand name

|

sinrad

|

|

model number

|

SR-FSS1

|

|

Dimension(L*W*H)

|

W1600 *D800*H1800mm

|

|

Operating Mode

|

Automatic

|

|

display

|

10 inch true color touch screen

|

|

Function

|

cut,dual end strip crimp and Wire Seal Insert

|

|

Wire Type

|

Cable, PVC, sheathed wire, etc., can be customized

|

|

Stripping range

|

front end 0.5~8mm, rear end 1-10mm

|

|

Cutting length

|

66mm-99999.99mm

|

|

Productivity

|

950 pcs/h (length within 80-150mm)

|

|

Air supply

|

0.4-0.8Mpa

|

|

wire applicable

|

AWG#14~22

|

|

detection

|

wire present, crimping or not,air pressure,Abnormal crimping

|