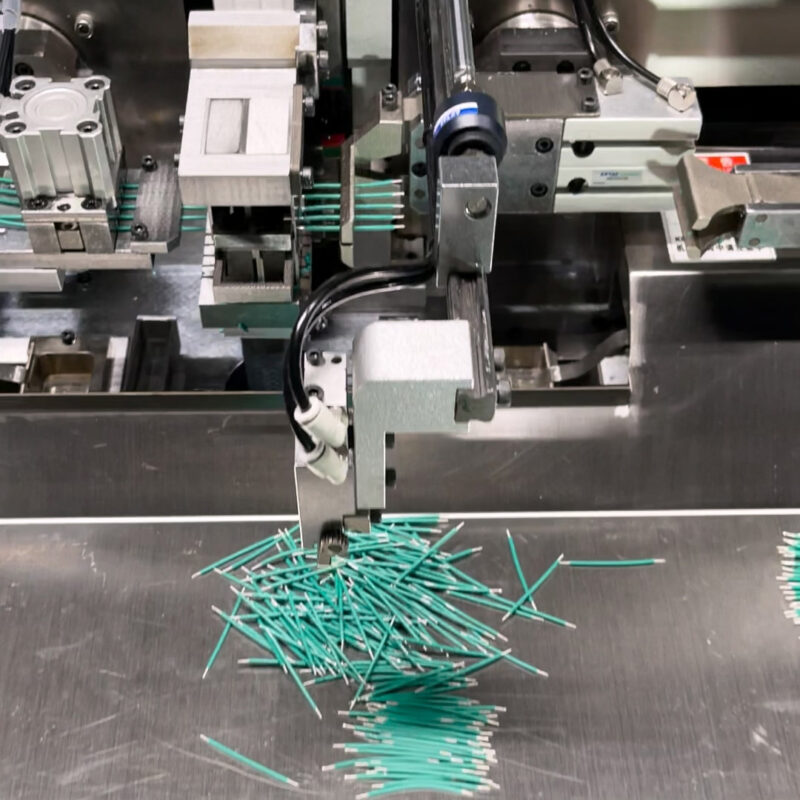

Fully Automatic Dual End Five Wire Stripping Twisting Tinning Machine for AWG18-32 Wire Harness Assembly

Integrated Multi-Functional Process: The machine seamlessly performs four critical functions in one pass: wire cutting, stripping, twisting, and tinning on both ends of the wire.

High-Speed and High-Quality Output: It offers impressive productivity of up to 8800 pieces per hour for 5-line wires within the AWG18-32 range. The machine ensures tight twisting and is designed not to damage the outer jacket, resulting in a low failure rate.

Precise and Customizable Parameters: All key processing lengths—including cutting (30-1000mm), stripping (0-12mm), twisting (3-12mm), and tinning (0-12mm)—are precisely adjustable and can be customized beyond the standard range.

Intelligent and User-Friendly Operation: The machine features a bilingual (Chinese/English) interface and a human-machine integrated design. It can store processing parameters for quick recall, eliminating the need for on-site debugging. It also has an error compensation system to correct for stripping length deviations.

Built with High-Quality Components: Key components are sourced from reputable brands, including servo motors and drives from Shenzhen Yaskawa/JMC, pneumatic cylinders from Taiwan Airtac, and linear guides and lead screws from Taiwan HIWIN, ensuring long-term reliability and precision.

|

Power

|

2000W

|

|

Weight (KG)

|

260

|

|

usage

|

Stripping twisting tinning

|

|

model number

|

SR-SZ01

|

|

Dimension(L*W*H)

|

180*72*145cm

|

|

Operating Mode

|

Automatic

|

|

applicable wire

|

AWG18-32# 0.316~0.81mm²

|

|

Stripping twisting length

|

0-12mm

|

|

Cutting length

|

30~1000mm

|

|

tinning length

|

3-12mm

|

|

Productive

|

8800pcs/h(depend on cutting length)

|

|

Power supply

|

AC220V/50Hz

|